The emergence of UVLED curing machines has brought pressure to some companies that are still using mercury lamps. In recent years, many manufacturers using mercury lamps have gradually replaced their equipment with UVLED curing equipment. What is the reason for UVLED curing equipment to replace mercury lamps? Height-LEDr summed up the following three reasons.

1. The pressure brought by environmental protection policies. In April 2016, the twentieth meeting of the Standing Committee of the Twelfth National People's Congress of the People's Republic of China decided to ratify the Minamata Convention on Mercury. This also indicates that mercury lamps will eventually be replaced by UVLED equipment in the future. Ozone is generated during the use of mercury lamps. At present, people pay more and more attention to environmental issues. If enterprises want to continue to develop, they need to cater to government policies.

2. Consideration of cost of use and production efficiency. Mercury lamps are slow to start and require complete cooling after being turned off. The service life of an ordinary UV mercury lamp is about 1000 hours, the electricity fee is 1.2 yuan/kWh, and it works for 10 hours a day, plus the cost of lamp replacement during the year, it is tens of thousands more than the mercury lamp of the same power. around expenses. Maintenance costs and electricity bills are much higher than UVLED curing machines.

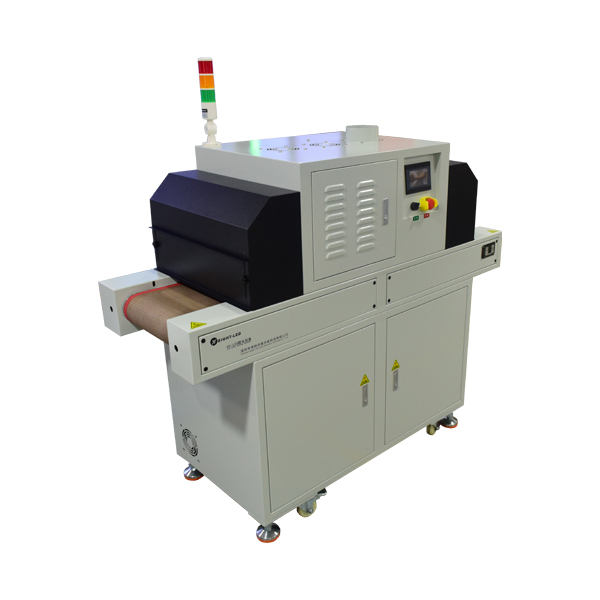

3. Operation convenience and safety. Nowadays, people yearn for smarter, simpler and safer work. UVLED mercury lamps not only occupy a large area and are difficult to clean, but also have a high temperature on the surface of the lamp. The mercury lamp must be preheated before use, and the power supply cannot be switched at will in order to ensure the stability of the equipment. The surface temperature of the lamp tube is high and the operator needs to be very careful. The UVLED curing machine uses chips and lamp beads that have undergone multiple reflow soldering processes, which can be turned on and off. convenient. Moreover, the UVLED curing machine also has a number of safety protection functions such as high temperature protection system, password protection function, lamp bead failure and so on.

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.